Here a sensor, there a sensor…

Meet a few faculty members in the College who are putting sensors to use in new ways.

Sensor technologies can be used to detect a wide range of inputs, from temperature and light to air pressure and ultrasonic waves. Across engineering disciplines, they are used by faculty members to collect data needed for groundbreaking work in energy, health care, manufacturing, infrastructure and more. Engineering researchers, it seems, are putting sensors everywhere.

Amay Bandodkar

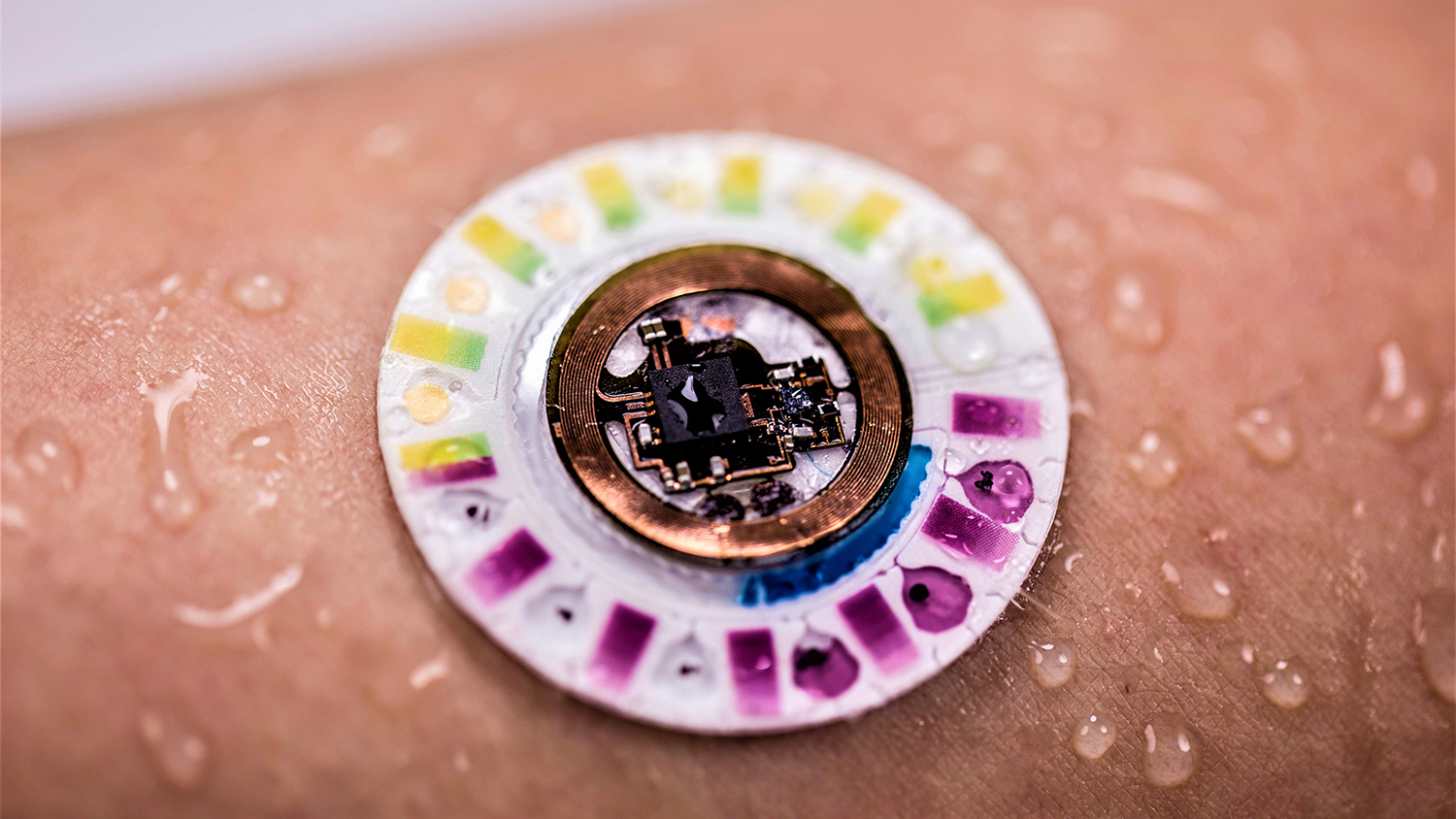

Amay Bandodkar’s work with the National Science Foundation Center for Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) led by NC State is helping to further the center’s mission of creating wearable health-monitoring devices that are powered by the human body and provide a range of data that will help wearers monitor their own health and inform their physicians’ care plans.

His unique work with biochemical sensors could help lead to health monitoring devices that are not just wearable, but can be implanted within the body, producing insights that help take these devices from fitness trackers to essential diagnostic tools for everything from pain to neurodegenerative diseases.

To help solve the problem of harvesting energy from the body to drive a monitoring device, Bandodkar turned to sweat. By using sweat as the electrolyte that supplies the electrical current to a device’s battery, he was able to build a sweat-powered, skin-friendly battery that requires only a tiny drop, 5 microliters, of sweat to power a wearable, wireless heart rate monitor.

Bandodkar’s work landed him on the MIT Technology Review 2021 list of Innovators Under 35 and a recent Newsweek list of the Greatest American Disruptors. He also recently received the 2021 Biosensors Young Investigator Award.

Mohammad (Moe) Pour-Ghaz

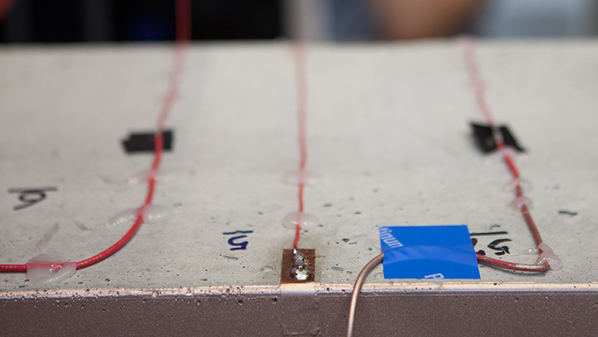

Mohammad (Moe) Pour-Ghaz uses electromagnetic sensors to study the durability of reinforced concrete materials and structures and fiber reinforced polymer (FRP) composites for use in civil infrastructure.

The “sensing skin” he designed can work as an early-warning system for concrete structures by measuring things like damage, the presence of damaging chemicals, strain and temperature. This data can point to small problems that may become larger problems, allowing a quicker response to damage in everything from nuclear facilities to bridges.

This skin is an electrically conductive coat of paint that can be applied to new or existing structures. Electrodes are applied around the perimeter of a structure. The sensing skin is then painted onto the structure, over the electrodes. A computer program runs a current between two of the electrodes at a time, monitoring and recording the electrical potential at all of the electrodes on the structure. This data is then used to calculate the sensing skin’s spatially distributed electrical conductivity. If the skin’s conductivity changes, that means the structure has cracked or been otherwise damaged.

Recent work will expand the skins’ capabilities from being used on flat, straight surfaces to allowing their use on three-dimensional structures of unusual shapes. Pour-Ghaz’s research group has collaborated with Aku Seppänen’s group at University of Eastern Finland in developing this technology.

Alper Bozkurt

Alper Bozkurt uses microscale sensors to unlock the mysteries of biological organisms with an aim of engineering these directly or developing new engineering approaches by learning from their biology. His use of sensors enabled remotely controlled insect cyborgs, helped train puppies as successful guide dogs and created wearables tracking health and environment of patients for asthma, diabetes and sleep disorders assessment.

Recent research looks to monitor plants and pests in crop fields, measure ecosystem health in partnership with mussels and improve comfort for amputees using prosthetics.

To provide more efficient monitoring of how pests learn to adapt to insecticides used to protect genetically engineered crops, Bozkurt’s team collaborated with NC State’s Department of Entomology and Plant Pathology to develop pheromone-based sensor platforms to study pest activity.

By using a sensor platform to remotely monitor the feeding behavior of freshwater mussels — when mussels feed, they open their shells; but if there’s something noxious in the water, they may immediately close their shells, all at once — Bozkurt and collaborators in NC State’s Department of Epidemiology hope to provide an early alert of the presence of toxic substances in aquatic ecosystems.

Work with colleagues in engineering and textiles is leading to a soft, flexible sensor system created with electrically conductive yarns that could help map problematic pressure points in the socket of an amputee’s prosthetic limb.

- Categories: