Next phase

Dr. Jagdish Narayan announced the discovery of a new phase of carbon in 2015 but offered a preview of that discovery in a paper published in the journal Science in 1991.

Dr. Jagdish Narayan announced the discovery of a new phase of carbon in 2015 but offered a preview of that discovery in a paper published in the journal Science in 1991.

The new phase, dubbed Q-carbon, was created by melting carbon and then quenching it with high-power nanosecond laser pulses. Q-carbon can be converted to diamond at ambient temperatures and pressures and could offer a lower-cost way to produce diamond that would serve a wide range of uses.

“This has been a big challenge for scientists all over the world to convert carbon to diamond at low pressures,” Narayan, John C. C. Fan Distinguished Chair Professor in the Department of Materials Science and Engineering (MSE), said. “We’ve always been hampered by thermodynamics.”

Narayan began working on the question 40 years ago, but understanding the thermodynamics — science said that carbon could only be a vapor or a solid, not a liquid — has taken decades.

Narayan wrote in that 1991 Science paper that the new carbon phase was possible, but exactly how it could be created was not yet known. Now it is.

“We said that under certain conditions we would be able to convert carbon into diamond,” he said. “We could not control those conditions.”

The discovery has made headlines worldwide. Narayan has given lectures on the discovery at five international conferences and four universities over the last three months. An easier, cheaper way to create diamond will have wide-ranging impacts, from energy exploration to healthcare.

“The response has been overwhelming,” Narayan said. “People are so excited about the possibilities ranging from diamond high-power devices for Internet of power highway to biomedical applications.”

Harder Than Diamond

Phases are distinct forms of the same material. Graphite is one of the solid phases of carbon; diamond is another.

Q-carbon has some unusual characteristics. For one thing, it is ferromagnetic – which other solid forms of carbon are not.

“We didn’t even think that was possible,” Narayan says.

In addition, Q-carbon is harder than diamond and glows when exposed to even low levels of energy.

“Q-carbon’s strength and low work-function — its willingness to release electrons — make it very promising for developing new electronic display technologies,” Narayan says.

But Q-carbon can also be used to create a variety of single-crystal diamond objects. To understand that, you have to understand the process for creating Q-carbon.

Researchers start with a substrate, such as sapphire, glass or a plastic polymer. The substrate is then coated with amorphous carbon – elemental carbon that, unlike graphite or diamond, does not have a regular, well-defined crystalline structure. The carbon is then hit with a single laser pulse lasting approximately 200 nanoseconds. During this pulse, the temperature of the carbon is raised to 4,000 Kelvin (around 3,727 degrees Celsius) and then rapidly cooled. This operation takes place at one atmosphere – the same pressure as the surrounding air.

The end result is a film of Q-carbon, and researchers can control the process to make films between 20 nanometers and 500 nanometers thick.

By using different substrates and changing the duration of the laser pulse, the researchers can also control how quickly the carbon cools. By changing the rate of cooling, they are able to create diamond structures within the Q-carbon.

Because it is harder than diamond, Q-carbon will open up new horizons for super-hard coatings, deep-sea drilling and biomedical applications.

“We can make Q-carbon films, and we’re learning its properties, but we are still in the early stages of understanding how to manipulate it,” Narayan says. “We know a lot about diamond, so we can make diamond nanodots, microdots, nanoneedles, microneedles and large-area single crystal thin films. We don’t yet know how to scale up and make Q-carbon and other structures inexpensively. That’s something we’re working on.”

Global Impact

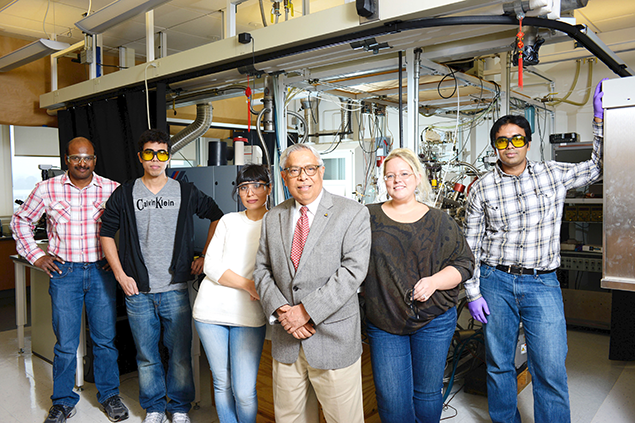

Narayan has received dozens of phone calls since publishing papers co-authored by MSE research assistant Anagh Bhaumik on the discovery in APL Materials and Journal of Applied Physics.

One of those calls was from a magazine that covers the cutting tool industry, including the diamond-tipped drills used in deep sea drilling. It’s possible that those drills could be sharpened with Q-carbon.

Diamond wheels are used to polish diamond with diamond, and those wheels wear out easily. Q-carbon, because it is harder than diamond, may offer a solution.

The possible applications go on from there.

“We can create diamond nanoneedles or microneedles, nanodots or large-area diamond films, with applications for drug delivery, industrial processes and for creating high-temperature switches and power electronics,” Narayan says. “These diamond objects have a single-crystalline structure, making them stronger than polycrystalline materials. And it is all done at room temperature and at ambient atmosphere – we’re basically using a laser like the ones used for laser eye surgery. So, not only does this allow us to develop new applications, but the process itself is relatively inexpensive.”

The most impactful area for Q-carbon, because it is expected to be a better electric conductor, may be in diamond electronics, which Narayan describes as the “holy grail” for high powered switches. These switches would power the next-generation power grid being developed by the Future Renewable Electric Energy Delivery and Management (FREEDM) Systems Center, a National Science Foundation Engineering Research Center based on NC State’s Centennial Campus.

NC State has filed two provisional patents on the Q-carbon and diamond creation techniques.

Narayan, for his part, will continue his work to learn more about this new form of carbon, the culmination of 40 years of work.

Return to contents or download the Spring/Summer 2016 NC State Engineering magazine (PDF, 3MB).

- Categories: