Manufacturing USA

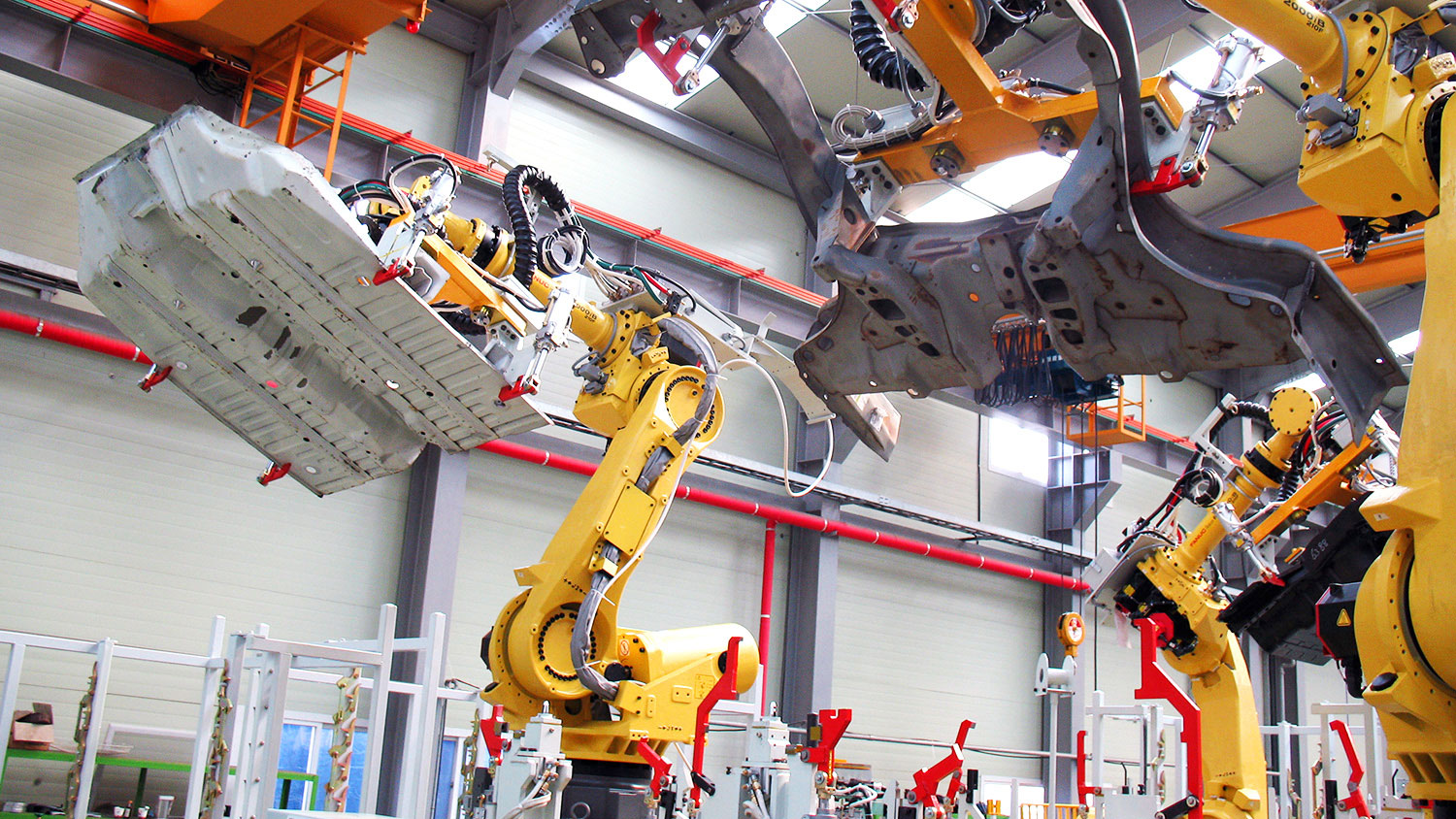

Manufacturing USA, launched in 2015, is a nationwide network of 14 public-private institutes, each of which focuses on a specific field of manufacturing technology. NC State is directly involved in seven of the 14 institutes — the most of any university in the country.

And while the technologies vary, all the institutes share a common goal: securing the future of manufacturing in the U.S. through innovation, collaboration and education.

“NC State’s role in Manufacturing USA is a result of the University’s reputation for fostering research and innovation with real-world impact,” said Chancellor Randy Woodson. “We have invested resources strategically and deliberately to align with industry needs. Our partnership in these institutes reflects that we’ve done this effectively, and it’s a credit to our breadth of experience and expertise.”

In 1978, manufacturing employed nearly 20 percent of the country’s overall workforce; today, it accounts for 9 percent. Manufacturing USA brings together partners from academia and the public and private sectors to revitalize industry and help the U.S. gain back lost ground.

“This is a big deal — not just for our work at NC State but for North Carolina and the country,” said Nick Justice, executive director of the PowerAmerica institute at NC State and chair of the national director’s council for Manufacturing USA. “Manufacturing is a core underpinning of our nation’s economy, and as it’s declined over the past several decades, we’re looking to build the new future of the industry and remain competitive.”

Across the University, experts are working to uncover new innovations and apply them directly to the industry. NC State is either the lead member or a participating member in the following institutes:

- PowerAmerica (Lead)

- Clean Energy Smart Manufacturing Innovation Institute (Southeast Lead)

- Advanced Functional Fabrics of America

- America Makes

- National Institute for Innovation in Manufacturing Biopharmaceuticals

- Digital Manufacturing and Design Innovation Institute

- Rapid Advancement in Process Intensification Deployment

“As the industry has changed, the country is looking to institutions like NC State for new technologies and processes to help manufacturers be more efficient, safer and more profitable,” said Dr. Phil Westmoreland, a professor in the Department of Chemical and Biomolecular Engineering (CBE)who leads NC State’s work with the Clean Energy Smart Manufacturing Innovation Institute (CESMII).

“When people think of manufacturing, they usually think of things like cars and large equipment,” Westmoreland added. “But in North Carolina especially, manufacturing also means using processes to make pharmaceuticals, biofuels and food products.

“Smart manufacturing gives us an opportunity to become leaders in collecting data and useful information so people can run processes better, make better business decisions, coordinate supply chains and maintain safe, clean operations.”

Ambition and Vision

“Centennial Campus has been focused on successfully growing public-private research and business partnerships for years,” Justice said. “We’re able to scale up quickly, and we have a proven track record of success for this type of work. When the opportunities came up for these institutes, it just made sense for NC State to demonstrate our expertise in the field.”

“NC State has the ambition and vision,” Westmoreland agreed. “That grows out of the strength of our state and region, as well as our mission as a land-grant university. We want North Carolina to be at the leading edge of learning around smart manufacturing.”

Addressing today’s challenges

NC State’s proven success in partnership was instrumental to the arrival of the newest Manufacturing USA institute on campus: the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL). The University’s track record in establishing and leading the Golden LEAF Biomanufacturing Training and Education Center (BTEC) — which helps educate and train students and industry professionals in biomanufacturing — makes NC State a strong partner for NIIMBL.

“BTEC will enhance what we’re able to do with NIIMBL — improving workforce development and helping us uncover new processes to ensure success for the industry,” said Dr. Ruben Carbonell, chief technology officer for NIIMBL and director of BTEC.

Carbonell, Frank Hawkins Kenan Distinguished Professor in CBE, added that the launch of an institute like NIIMBL couldn’t be more timely.

“The U.S. was a leader in the first wave of the biopharmaceutical manufacturing industry; we’ve essentially dominated the field for two decades. But other countries are catching up and investing in smarter technologies. We now have to produce products that are cheaper and more widely available, without compromising safety. That’s our challenge, and if we’re successful, that means more jobs and expanded industry here at home.”

Although some of the institutes are still in the initial phases of setup and research, leaders look forward to the contributions NC State will make to the industry as a whole.

“We can all learn from each other,” said Carbonell. “That’s the beauty of the collaborative environment we’ve built at NC State.”

NC State Is Directly Involved in Seven of the 14 Institutes

Clean Energy Smart Manufacturing Innovation Institute

Real-time feedback can help companies make better decisions that save money and increase efficiency. With leaders from NC State, CESMII aims to improve output and measurement for 12 industry sectors, including food and beverage, aerospace, paper and pulp, and plastics.

PowerAmerica

Better charging stations for electric vehicles, more efficient cars and power distribution centers, and more compact power adapters for consumer electronics. Through PowerAmerica, NC State and other partners seek to make these breakthroughs possible by accelerating the adoption of wide bandgap semiconductor technologies.

Rapid Advancement in Process Intensification Deployment Institute

How do we make the manufacturing process cleaner and more efficient? NC State, through the Rapid Advancement in Process Intensification Deployment Institute, seeks to answer that question and make the manufacturing industry stronger for the future.

Digital Manufacturing and Design Innovation Institute

Data from the National Science Foundation ranks NC State No. 7 in the country among public universities without a medical school for total research expenditures — and third for industry-sponsored research. A driving force behind that success is the University’s Centennial Campus, home to more than 70 industry, government and nonprofit partners, including many of the researchers involved in Manufacturing USA.

America Makes

Additive manufacturing and 3-D printing technology are rapidly evolving. America Makes, in partnership with NC State, is on a mission to innovate and accelerate additive manufacturing and 3-D printing technologies to increase the U.S.’s global manufacturing competitiveness.

Advanced Functional Fabrics of America

Wearable tech that can see, hear, sense and communicate? Through Advanced Functional Fabrics of America, NC State is helping to make these types of textiles and fibers widely available and smartly produced.

National Institute for Innovation in Manufacturing Biopharmaceuticals

The United States has been the global leader in biopharma for decades, but other countries are catching up. Through NIIMBL, NC State is working to accelerate U.S. innovation in the field, improve efficiency, and educate and train a world-leading workforce.

Return to contents or download the Fall/Winter 2017 NC State Engineering magazine (PDF, 6.8MB).

- Categories: