By Sarah Stone

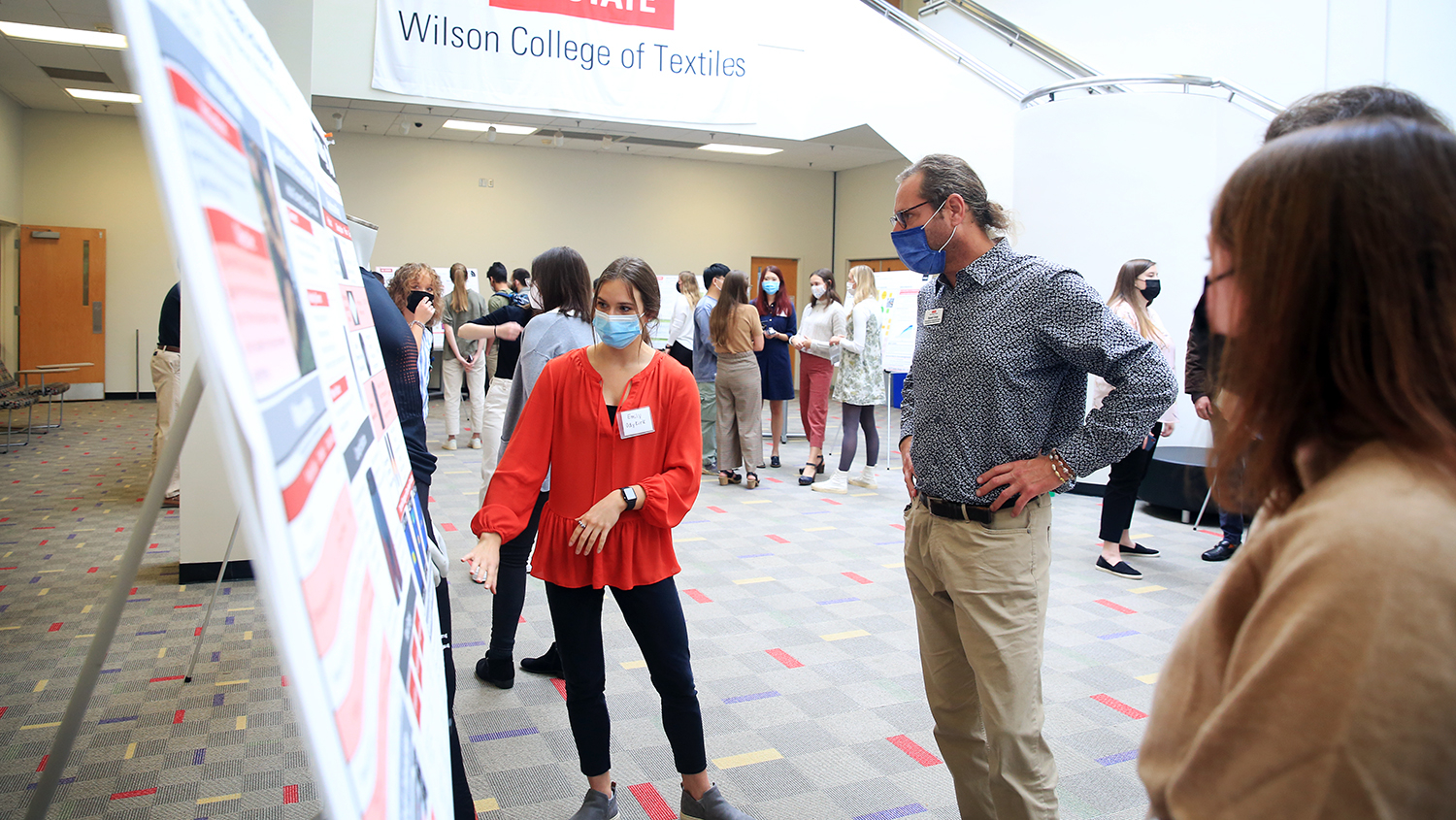

Students from the Wilson College of Textiles shared their ideation, research and testing during Friday’s Senior Design poster session. The event presented the opportunity to hear feedback from experts as well as practice presentation skills.

Senior Design is a year-long course that pairs teams of textile engineering (TE) and textile technology (TT) students with sponsors ranging from startups to industry giants to adjust testing methods, create processes, develop products and more. Before meeting their sponsors, teams began the year with a crash course product design called the Rice Bag Challenge.

Below, read about a few of the real world problems that Senior Design teams are tackling this academic year.

Marissa, Robert and Ryan are developing the first product for a startup called AVEC. The company is a partnership between a physical therapist and his patient.

“What they found is that taping the foot and adjusting that posture in your foot and ankle builds a foundation that improves the health of your knees and hips, which helps support your back,” TE student Robert Seevers explains. “So the idea is taking that base and supporting it in a way that impacts and improves other areas of your body.”

This Senior Design team’s task is to combine those findings with their textile knowledge to create a sock that replicates this taping method in a more convenient and comfortable way.

Claire, Molly, Chenlu and Yu are advancing sustainability in the apparel industry in partnership with PVH. You might not have heard of the corporation, but you’ve certainly heard of its brands: Calvin Klein and Tommy Hilfigher to name a few.

This Senior Design team is helping these industry leaders determine the best mechanical or chemical process to turn post-consumer underwear into fibers that can be recycled elsewhere.

Brandon, Chris and Jacqueline are working with The North Face to produce alternate dobby weave ripstop designs for The North Face. Ripstop is one of the company’s most recognizable fabrics. You’ll notice it in products ranging from backpacks to tents to jackets.

The company is looking for something more exciting than the classic ripstop square.

“They want a design that will look fresh and still provide the same strength and tear resistant capabilities as classic ripstop would,” TT student Brandon Postema-Drolet says.

Gunikka, Maddie and Owen’s project will improve sustainability for the U.S. Army while also keeping its members safe.

Employees at Pine Bluff Arsenal have to use special protective suits while they interact with hazardous chemicals, but right now, those suits can only be worn about three times before becoming obsolete. The Army wants a protective suit for these members of the service that can be laundered, and this Senior Design team is figuring out how to make that happen.

Overcoming Product Development Challenges

Students say that since they were first assigned their sponsors in early September, they’ve been able to chart a clearer direction for their team.

“I think what I found most difficult is not necessarily being able to make our ideas in their entirety to really see how they perform. Instead, we are having to use benchmarks and products to stand in for our ideas and concepts and use them to quantify our decision of our concept,” senior TE student Robert Seevers says. “So that’s taken a little bit of mental gymnastics.”

Students are also learning to work within the constraints and redirection of their sponsors.

“Getting our solution implemented in one to two years was a big thing for our sponsor,” senior TE student Claire Henson says. “We thought that creating a whole new yarn could be really cool. But our sponsor told us that’s not going to work in a short time, so we had to get creative and think outside the box.”

In order to carry out their ideas, most groups have had to come up to speed quickly on areas they’ve never studied before.

“Learning all the aspects of fabric creation has been a little challenging. We still haven’t wrapped our heads fully around it yet,” senior TT student Brandon Postema-Drolet says. “We’re still learning how to calculate different fabric weights and what we want our average weight to come out to be and how that’s going to also affect our strength values.”

Polymer chemistry, sourcing and knitting technology are just some of the other subject areas that seniors are having to familiarize themselves with in order to carry their plans to fruition. That’s where Wilson College professors and their expertise come in handy.

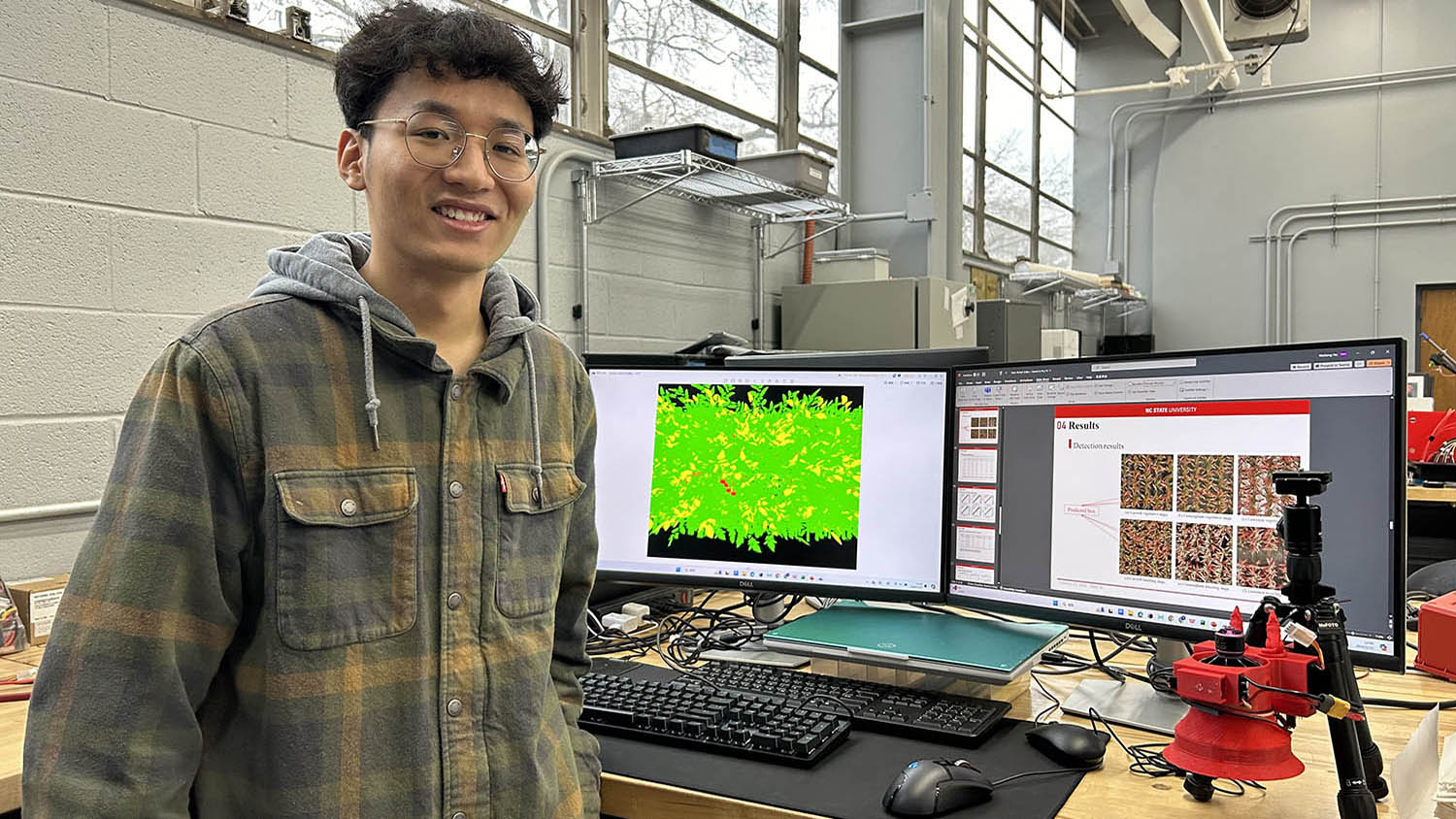

“We’ve reached out to many professors and some of them have really helped us a lot,” TT student Yu Yan says.

During Friday’s poster presentation, professors, graduate students, staff and industry professionals all stopped by to provide feedback and ask questions.

“Assistant Professor Ericka Ford has told us to really look into more of how the nonwoven is being produced,” TT student Maddie Wilson says. “To look at different production levels and some of the bonding techniques for the nonwoven.”

Next, teams will incorporate the suggestions they received Friday and start putting their ideas to the test with prototyping.

This post was originally published in Wilson College of Textiles News.