The right space

Fitts-Woolard Hall provides the environment that faculty members and students need to succeed

Kevin Han joined the faculty of the Department of Civil, Construction, and Environmental Engineering (CCEE) in 2016. With the opening of Fitts-Woolard Hall, his research group now has laboratory space.

Han, an assistant professor, conducts research creating and using existing computer vision and machine learning analytics that leverage visual data and Building Information Modeling to improve communications, efficiency and safety in construction sites.

In Mann Hall, CCEE’s home on North Campus since the building opened in 1964, Han had his own office and offices for graduate students. But, because of limited availability of laboratory space in the building, he and his group had to conduct their research in the Constructed Facilities Laboratory (CFL) on Centennial Campus. Mann and the CFL are a couple of miles away from each other. And because the CFL is a shared facility, they did not have their own desks or dedicated space for storage and conducting experiments.

“It was definitely not convenient,” Han said.

In Fitts-Woolard Hall, the College’s newest building on Centennial, Han has a dedicated lab on the first floor with open space and high ceilings. His graduate students are using a shake table, which can be used to test the seismic performance of structures, to test whether a visual monitoring system can gather data on the structural performance more effectively than an accelerometer.

Moving to Centennial will also make it easier for Han to interact with colleagues he collaborates with in mechanical and electrical engineering and in computer science.

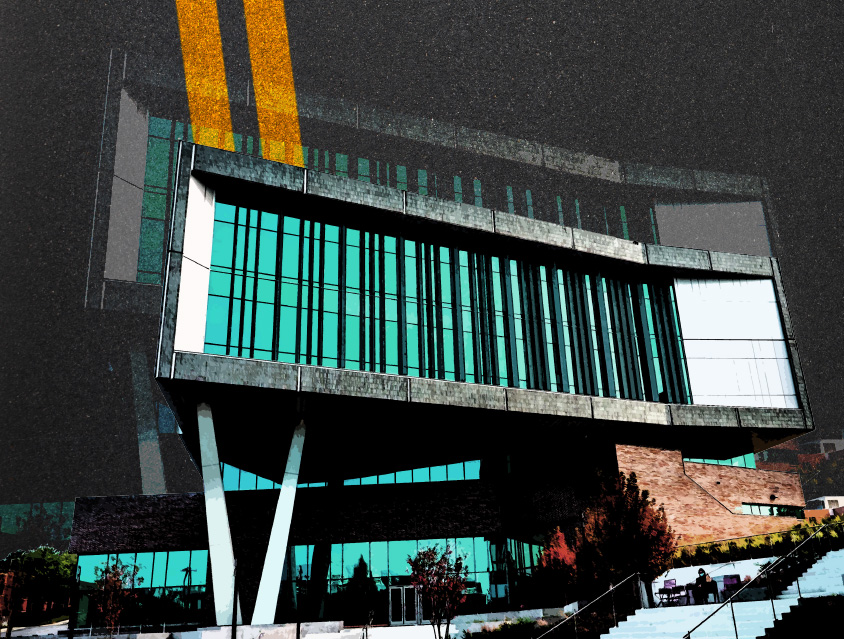

Fitts-Woolard Hall, which opened in summer 2020, is the new home of CCEE, the Edward P. Fitts Department of Industrial and Systems Engineering (ISE) and the dean’s administrative offices.

The College now has eight of its nine academic departments on Centennial Campus. It’s part of a decades-long process to move the entire College over and take full advantage of one of the country’s most innovative academic research campuses. Unifying on Centennial will give the College the tools needed to take a place as one of the preeminent public colleges of engineering in the United States.

“The opening of Fitts-Woolard Hall represents a tremendous step forward in reaching our full potential,” said Louis Martin-Vega, engineering dean. “We are getting much closer to completing a vision for the College.”

Current and future needs

For CCEE and ISE, the move means leaving behind antiquated facilities that don’t match up with the ways in which today’s cutting-edge engineering research is conducted, either in capacity or functionality.

ISE moved out of the former Daniels Hall (known today by its street address — 111 Lampe Dr. — until it is renamed), which opened in 1926.

Unlike in Fitts-Woolard Hall, laboratory spaces in both buildings were inflexible. When additional electrical capacity was needed to power labs in Mann Hall, the department and College had to consider sizable investments in infrastructure, or just go without.

Cassie Castorena, an associate professor in CCEE who is part of a team of researchers in the department working on asphalt materials, ran into that electrical capacity problem in Mann. Her research team worked in several rooms in the building’s basement.

“I don’t know if any of those spaces were originally intended for the purpose that we were using them for,” she said.

Castorena didn’t have dedicated space in Mann for her group’s unusual storage requirements — they use a lot of asphalt binder and aggregate materials. They utilized space next door in Broughton Hall and in University surplus facilities on another part of campus. Now, she has a 7,000-square-foot lab space that is functional, with adjacent storage capacity.

“It meets all of our current needs, and I anticipate it will meet all of our needs in the future,” she said.

Laboratory spaces in the old buildings also weren’t very accessible. That’s not the case in the new facility, which uses “engineering on display” as a design concept. Labs on the first two floors of the building are placed in prominent spots with floor-to-ceiling glass walls so that visitors can see the important work that is going on inside.

ISE’s Center for Additive Manufacturing and Logistics (CAMAL) occupies a prominent spot on the second floor and is visible from outside the building on the Engineering Oval and in the lobby.

In 111 Lampe, CAMAL had six additive metal printers in the same room. The risk of cross-contamination severely limited when the machines could be run and necessitated a lot of extra time spent cleaning. A storage room where the powders used in the machines was kept was not close enough to be efficient, said Ola Harrysson, CAMAL director and Edward P. Fitts Distinguished Professor in ISE.

In the new building, each machine has its own room with its own HEPA filter and materials storage nearby in what is referred to as the “clean corridor.” CAMAL’s machines are arranged in a much more efficient layout so that teaching machines, which often are crowded with students, aren’t close to higher-end machines.

Nearby, the Fincher Lab provides the same flexibility for student groups in CCEE.

The space used by the groups in Mann Hall was next to a loading bay (students had to stop their work if a delivery was coming in) and each group had to use the same fixed benchtop. In the new space, each group has its own rolling tool chest.

“This allows us to make this space into whatever project function is needed at the time,” said Steve Welton, a senior lecturer in CCEE who serves as a faculty advisor for a few of the groups.

The space has a high ceiling, plenty of storage and good natural light from the outside. It’s well ventilated and features an eye wash station. Plus, in keeping with the engineering on display concept, it’s in a prominent spot on the first floor where other students can see what the groups are doing and potentially take an interest in joining.

The Earthquake Engineering Research Institute student chapter uses Fincher Lab as a working area to build and test structures that can help promote students’ knowledge of structural engineering and seismic design, said chapter president and Ph.D. student Jessi Thangjitham.

The lab is home to the chapter’s shake table and offers a working space for students to build a 17-story balsa wood structure under realistic earthquake ground motion for an international Seismic Design Competition.

Closing the gap

The project represents a new funding model for NC State and the UNC System, with the College pledging to raise $60 million toward the cost of construction through private philanthropy. Thanks to the generous $25 million gift from engineering alumni Edward P. Fitts and Edgar S. Woolard and commitments made by more than 400 alumni and friends, the College has just over $49 million in pledges — leaving an $11 million gap to fill.

Though the building may be complete, the College continues to seek support from alumni and asks them to step up and help fill the funding gap. If you are interested in learning more about fundraising efforts for Fitts-Woolard Hall, please contact Hannah Kunkel with the NC State Engineering Foundation at heallen3@ncsu.edu or 919.515.7458.

Return to contents or download the Spring / Summer 2021 NC State Engineering magazine (PDF, 52.0 MB).

- Categories: