Engineering Communications

Engineering Communications provides award-winning services and support for the College of Engineering at NC State University.

What We Do

Engineering Communications provides a variety of services for the college including publications planning, graphic design, layout, writing/editing, web design, media relations, marketing, print spec writing, securing print bids and more.

Whatever your department or unit needs, we’ll work with you to ensure collaborative, effective and successful communications.

Need a logo or icon? Not sure which color to use?

Find what you are looking for here!

Portfolio

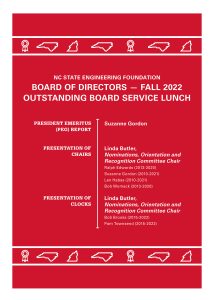

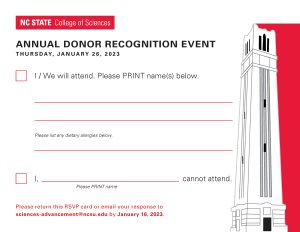

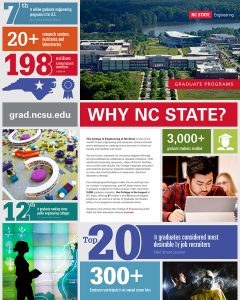

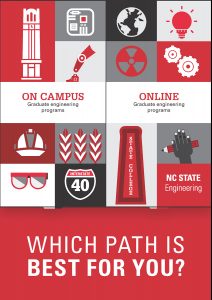

Graphic Design & Publications

View collection

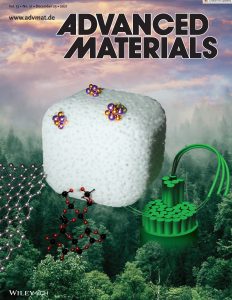

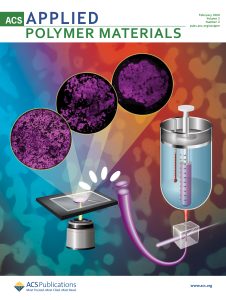

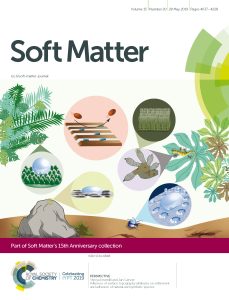

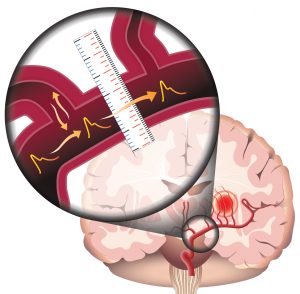

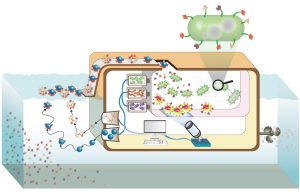

Technical & Scientific Illustrations

View collection

Click/tap images below to view larger versions.

Magazine

Engineering Communications publishes a semi-annual magazine devoted to highlighting alumni, students, faculty and staff.

Awards

- CASE District III Bronze Award (2020), Design, Periodicals and Magazines, NC State Engineering Alumni Magazine / Spring 2020

- CASE District III Bronze Award (2020), Unpublished Work: The illustration for the center of Closed Loop Engineering for Advanced Rehabilitation (CLEAR) at NCSU

- Diane McGurgan Service Award (2017), National Association of Science Writers

- CASE District III Special Merit Award (2015), Print and Digital Publications: Magazine/Tabloid Improvement II, “Incorporating the New Brand for NC State Engineering magazine”

- CASE District III Award of Excellence (2010), Magazine Publication Improvement

- CASE District III Special Merit Award (2010), Alumni Magazines II

- CASE District III Grand Award (1998), General News Story or Series Division for “NC State Engineer Works on Artificial Retina Design”

- CASE District III Award of Excellence (1998), General News Story or Series Division for “NC State Engineers Test New Ways to Monitor, Control Swine Odor”

- CASE Gold Medal Award (1997), General News Writing

- CASE Grand Gold Medal Award (1997), Excellence in News Writing

Meet Our Team

Contact Us

Office

Research IV

909 Capability Drive, Suite 1800

Campus Box 7282

Raleigh, NC 27695-7282

Phone

919-515-3394

Hours

Monday: 8 a.m. – 5:00 p.m.

Tuesday: 8 a.m. – 5:00 p.m.

Wednesday: 8 a.m. – 5:00 p.m.

Thursday: 8 a.m. – 5:00 p.m.

Friday: 8 a.m. – 5:00 p.m.

Saturday and Sunday: closed